Development at Proseat

Everything under one roof

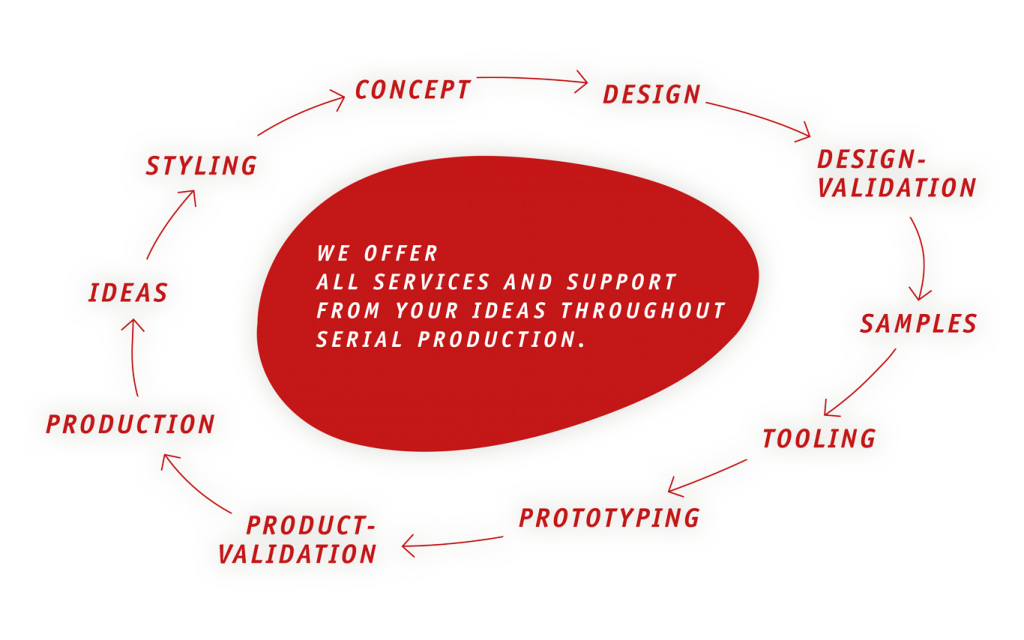

Our goal is the transfer of the ideas of our customers into best-in-class serial products – using the state-of-the-art technologies, engineering support systems and optimized agile processes.

Always in focus: the consideration of tomorrow’s economic and environmental requirements.

Our Development Cycle

Validation at Proseat

Meeting everyone’s needs

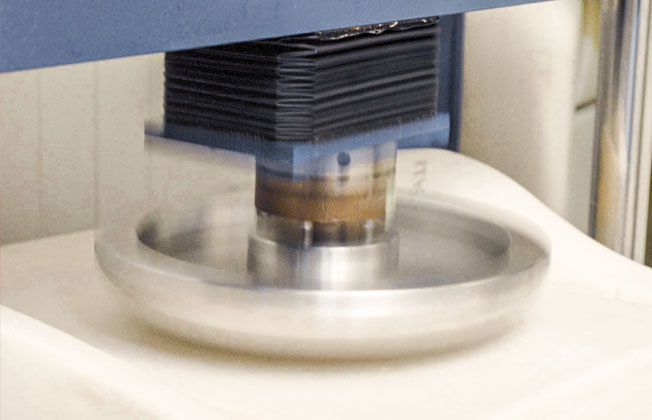

With our products in millions of vehicles and enduring the daily demands of the road. Proseat products have to meet the most stringent of quality requirements. This requires extensive monitoring, simulations and load tests – all part and parcel of our development process. With our testing labs and our certified partners, we validate our production processes as well as the quality of our parts.

Technology at Proseat

High tech for your success

Proseat offers our customers high-quality products that have been tried and tested millions of times over. Using the latest technologies, software solutions and our manufacturing expertise, we develop, test and produce our products all in our own development centers and plants, always in close cooperation with the customer. At the forefront of this is keeping our processes lean – a challenge our colleagues in project management and production repeatedly solve, for everyone’s benefit.